Stone Benchtops

Sunshine Coast

- Servicing the Sunshine Coast since 2009

- Fast & efficient project turnarounds

- Custom stone products to suit every space

Sunshine Coast Stone Benchtops

Getting a stone benchtop should feel exciting—not overwhelming. At Stone Effects, we simplify the process for Sunshine Coast clients by managing everything in-house, from the initial enquiry to final installation.

Whether you’re after a standout island bench, a refined bathroom vanity, or tailored finishes using sintered stone, natural stone, or mineral stone, we guide you through every step. Our goal is to create a surface that fits seamlessly into your space, matches your style, and performs for years.

Engineered stone is available in two standard sizes:

- 3000mm x 1400mm

- 3200mm x 1600mm (±50mm)

Weight of engineered stone:

- 20mm thickness weighs approximately 50kg/m²

- A full slab weighs around 250kg

Natural stone comes in more varied sizes, typically ranging from:

- 2800mm–3200mm in length

- 1700mm–2100mm in width

Call

(07) 5355 0410

to chat with our Sunshine Coast team about what’s possible for your stone benchtop.

Our 5-Step Stone Benchtop Process

Ordering your new stone benchtop is a smooth and seamless experience with our simple 5-step process. Here’s what to expect:

Step 1

Stone Selection & Design Details

Begin by exploring our extensive range of stone options, including Mineral Stone, Natural Stone, and Sintered Stone. During this stage, you’ll also finalise important design elements such as your preferred edge profile and any other custom details to suit your space.

Step 2

Quoting

Once your selections are confirmed, we’ll provide a comprehensive quote based on your final choices. This gives you a clear understanding of the project scope and cost before moving forward.

Step 3

Laser Check Measure

Our team will complete a precise laser check measure to ensure all dimensions are exact. This process also allows us to identify any potential site challenges before fabrication begins, helping to ensure a flawless installation.

Step 4

Expert Fabrication

Your chosen stone is then crafted by our skilled team of experienced stonemasons. Using quality equipment and attention to detail, we transform raw slabs into beautiful, custom benchtops built to last.

Step 5

Professional Installation

The final stage is the installation of your new benchtops by our expert installation team. With care and precision, we bring your vision to life—delivering a stunning finish you’ll love for years to come.

Manufactured for Everyday Living

A good stone benchtop doesn’t just look the part—it works for how you live. We build with function in mind, whether you’re a home cook, a growing family, or fitting out a commercial space. Want waterfall edges? Flush-mounted appliances? Integrated splashbacks? We make it happen.

Our focus is on delivering a stone benchtop that feels right for your home and holds up to everyday life. By handling the full process ourselves, we make sure the final result reflects your needs and style—no gaps, no surprises. The right stone, properly fitted, brings your whole space together.

Our Bench Top Edge Profiles

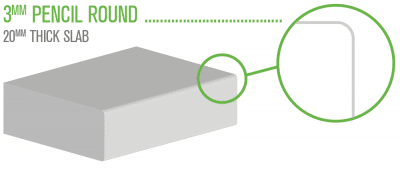

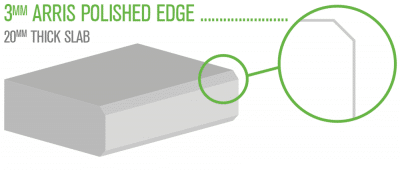

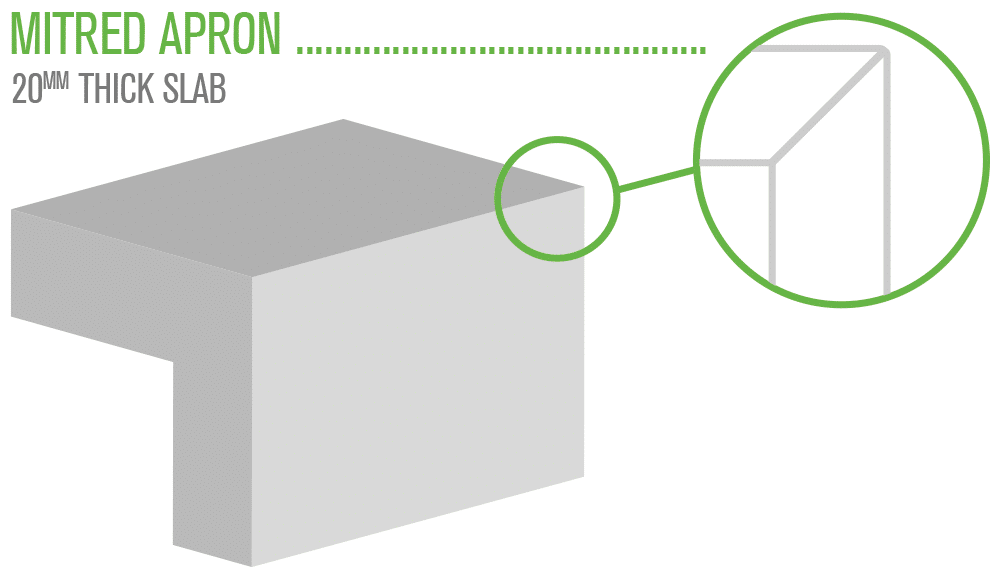

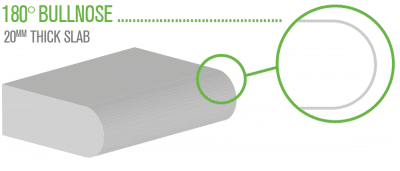

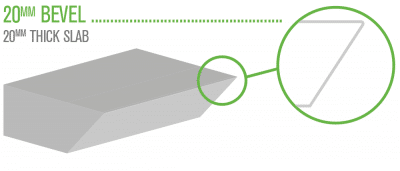

20MM EDGE PROFILES

20mm Pencil Round

20mm Arris Polished

Mitred Apron

180° Bullnose

20mm Bevel

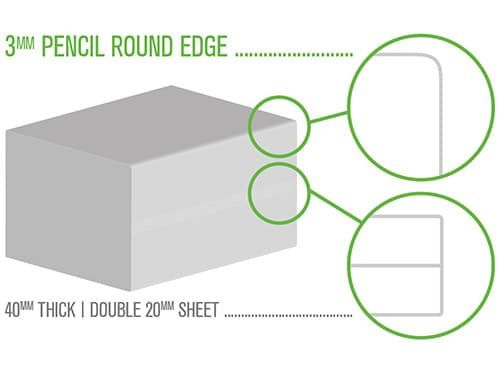

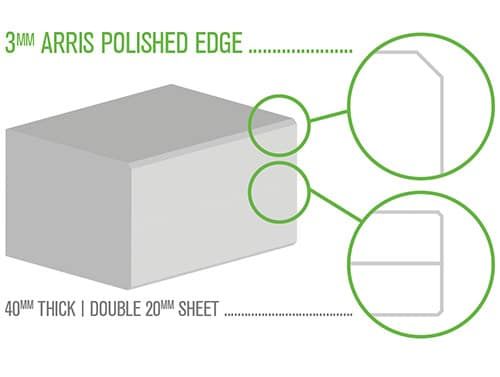

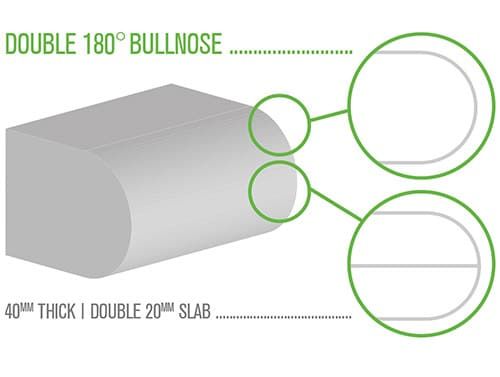

40MM EDGE PROFILES

40mm Pencil Round

40mm Arris Polished

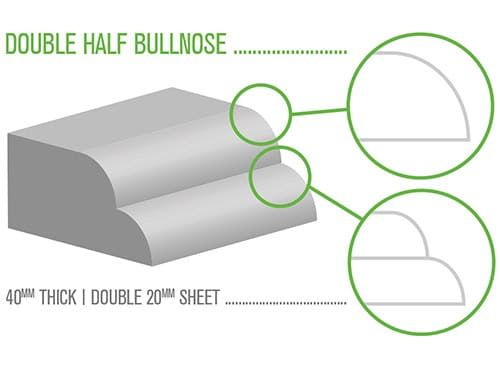

Double 180° Bullnose

Double Half Bullnose 40mm

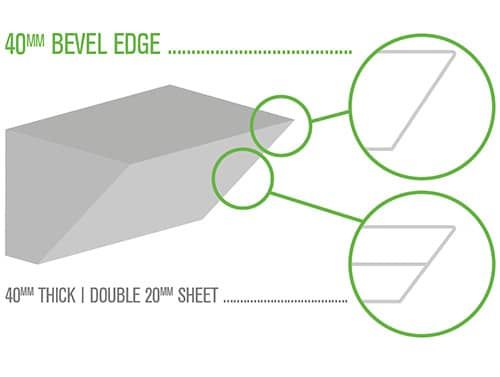

40mm Bevel

Frequently Asked Questions

What sizes and weights do stone benchtops come in?

Engineered stone slabs generally come in two standard sizes: 3000mm x 1400mm or 3200mm x 1600mm, with a size tolerance of around ±50mm. These slabs are dense and heavy—a 20mm thick engineered stone weighs approximately 50kg per square metre, meaning a full slab can weigh up to 250kg.

Natural stone, on the other hand, varies more in size depending on the type and source, typically falling between 2800mm and 3200mm long, and 1700mm to 2100mm wide.

What stone finishes are available, and do they affect maintenance?

Stone slabs—whether engineered or natural—are available in a wide range of finishes, including polished, honed, matt, concrete and rough textures. While each finish offers a different aesthetic, it’s important to consider how they affect day-to-day maintenance.

Textured surfaces like matt or rough finishes can trap more dirt and residue, requiring more regular and thorough cleaning than polished or honed surfaces. If easy cleaning is a top priority for your benchtop, it's worth keeping this in mind.

Will my benchtop need a join, and will it be visible?

Depending on your kitchen layout and access, a site join may be necessary. If we need to navigate tight staircases, narrow doorways, or tricky corners, installing a single, seamless slab may not be possible. In these cases, a join allows us to safely install the benchtop in sections.

Site joins are also common in many kitchen styles, regardless of access. While our installers are highly skilled at colour-matching the glue to your stone, the join will be visible on close inspection—though neatly done and discreet.

Can I customise cutouts and edges on my stone benchtop?

Absolutely. With our advanced CNC (computer numerical control) equipment, we can offer a wide range of precise cutouts and edge finishes. Beyond standard top-mount and undermount sink cutouts, we can also create flushmount cutouts, recessed drainer boards, and drainer grooves to enhance both function and style.

Edge profile options are equally flexible—we can craft styles like lambs tongue with excellent accuracy, giving your benchtop a bespoke, high-end finish that complements your kitchen aesthetic.

Can you customise benchtops for odd layouts or unique designs?

Yes. We design and manufacture custom stone benchtops to fit tricky kitchen corners, unusual vanities or bespoke commercial spaces. We measure, fabricate and install so your surface fits neatly and looks just right.

How do I care for a stone benchtop to keep it looking its best?

To care for your stone benchtop, wipe spills promptly and clean with warm water and mild detergent. Avoid harsh chemicals and use soft cloths or sponges. For natural stone, reseal periodically to guard against stains and moisture.